Financial News

Why choose a low-smoke halogen-free sheath for PV cables complying with EN50618 standard?

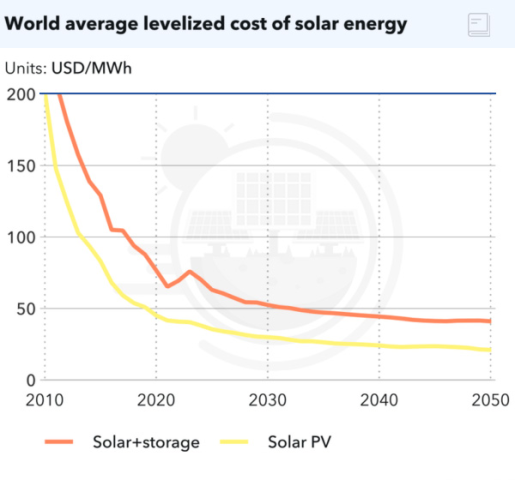

By the mid-21st century, solar power generation is expected to remain the cheapest source of energy in the world, with a total installed capacity of 15.3 terawatts (TW), a 13-fold increase compared to 2022. According to the "2023 Energy Transformation Outlook," it is anticipated that a significant portion of the global increase in solar PV capacity will include storage.

As the global renewable energy market rapidly expands, the demand for solar cables is also on the rise. EN50618 is a standard for PV cables that specifies the design and performance requirements of PV cables, including the choice of insulation and sheathing materials. Below, we will discuss the insulation and sheathing material options under the EN50618 standard.

PV cables must be able to operate for extended periods in harsh outdoor environments, making the selection of appropriate insulation and sheathing materials crucial. According to the TUV EN50618 standard, here are some common insulation and sheathing material options:

Polyethylene (PE) Insulation and Sheathing: Polyethylene is a common insulation and sheathing material known for its good electrical insulation properties and weather resistance. It is typically used for general PV cables.

Cross-Linked Polyethylene (XLPE) Insulation and Sheathing: XLPE materials offer higher electrical insulation performance and heat resistance, making them suitable for PV systems that need to withstand high temperatures.

Ethylene Propylene Rubber (EPR) Insulation and Sheathing: EPR materials exhibit excellent heat and cold resistance, making them suitable for solar cables in extreme weather conditions.

Silicone Rubber Insulation and Sheathing: Silicone rubber performs well at high temperatures, making it suitable for PV systems operating in high-temperature environments.

Additionally, XLPO is a special type of cross-linked polyethylene that has undergone cross-linking treatment to improve its performance, making it suitable for specific applications. XLPE is commonly used as the insulation material for wires and cables due to its excellent electrical insulation performance, thermal stability, and weather resistance, all of which are crucial for ensuring the reliability and safety of power transmission and distribution.

Based on the comparison above, it's clear that XLPO is the best-performing cable insulation material. Therefore, when selecting cable insulation materials, it's advisable to choose a supplier that offers XLPO-insulated cables. Some reputable brands in the market that meet these requirements include KBE and KUKA CABLE.

KUKA CABLE's products not only comply with the EN50618 standard but also utilize advanced XLPO materials and employ EVA and EMA copolymer blending technology to ensure the stability and durability of the cables in various environmental conditions. Currently, these cables have been exported to over 120 countries.

In the PV industry, selecting the right cable materials is crucial as they directly impact the performance and reliability of PV systems. According to the EN50618 standard, understanding the choice of insulation and sheathing materials is a critical step in ensuring the success of your project. KUKA CABLE is an outstanding PV cable supplier, providing reliable cable solutions for customers in the renewable energy sector.

Media Contact

Company Name: KUKA CABLE

Contact Person: Media Relations

Email: Send Email

Phone: 0086-18317109559

Address:Building 15, No. 9655, Tingwei Highway, Tinglin Town, Jinshan District

City: Shanghai

Country: China

Website: https://www.kukacable.com/

Stock quotes supplied by Barchart

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the following

Privacy Policy and Terms and Conditions.