Financial News

Markforged Introduces FX10, The Most Versatile Tool Designed For The Factory Floor

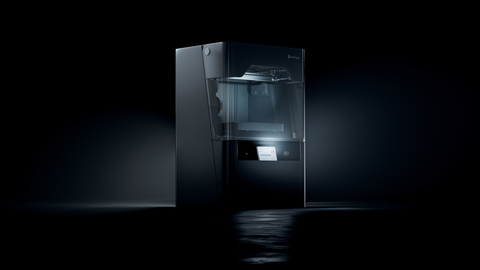

The fifth-generation print system features built-in automation for quality assurance and print routines designed to deliver strong, accurate parts every print

Markforged Holding Corporation (NYSE: MKFG), the company strengthening manufacturing resiliency by enabling industrial production at the point of need, today unveiled its newest industrial 3D printer, the FX10. Continuing Markforged’s heritage of reliable printers that deliver strong, precise parts, the FX10 is designed to supercharge manufacturing line productivity and profitability. The FX10 empowers users to print the right part when and where it is needed, reducing costs and cutting lead times from months to days compared to traditional manufacturing methods.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20231107499924/en/

The FX10 features built-in automation for quality assurance and print routines designed to deliver strong, accurate parts every print. (Photo: Business Wire)

“We engineered the FX10 to be the best tool for the manufacturing floor,” said Shai Terem, CEO of Markforged. “The FX10 allows manufacturers to slash original part replacement costs when compared to traditional methods and keep production lines running without worrying about supply chain issues or spare parts inventory. The FX10 can accelerate the digitization of the manufacturing floor by increasing the adoption of digital inventory to build supply chain resiliency. Our customers now have the potential to save even more capital by reducing physical inventory and boosting production yields while decreasing operating costs.”

Designed with flexibility in mind, the printer's modular systems are engineered to be expanded and upgraded with additional capabilities. For example, the FX10 has been designed to incorporate a printhead integrated vision module to capture detailed part images and data to further ensure part quality and optimize printer performance. The 5th Generation Continuous Fiber Reinforcement (CFR) print system delivers high print quality in a heated print chamber allowing for print speeds that are nearly twice as fast and print sizes that are up to twice as large as previous Markforged industrial series printers, enabling the replacement of metal parts with advanced composites.

“The FX10 is another important milestone in our mission to bring industrial production to the point of need. It enables our customers to address even more industrial applications with clear return on investment. Coupled with our Digital Source platform, we are truly starting to bring the vision of distributed manufacturing into reality,” said Terem. “The FX10 features a full suite of automation built to simplify the usage of the printer and increase adoption to build resiliency into our customers' production. When a line is down, or a tool is needed, FX10 users can simply Press Print.”

The FX10 was designed to ensure easy adoption on the manufacturing floor starting with the first line operator. A simple touchscreen interface combined with new automation and quality assurance technologies enable users to get more parts out of the FX10 with fewer interactions needed by the operator before and during a print than with previous Markforged printers.

The printhead-mounted optical sensors automatically verify the dimensional accuracy of parts during the print to ensure consistency and reliability, while also assessing machine health and performance. The laser micrometer in the FX10 scans parts during printing and assists with the machine’s automatic calibration. Inspection software interprets the data from the sensors for dimensional verification, providing users with quality assurance as soon as a print finishes.

The material drawer of the FX10 contains built-in, individually sealed storage bays for up to four 800cc spools. FX10 is able to automatically execute spool changeovers between filament storage bays during a print, and users can reload empty spool bays without disrupting a print.

The Digital Forge is the additive manufacturing platform for modern manufacturers that enables every aspect of the FX10. A complete additive manufacturing platform consisting of printers, cloud-enabled software with process improvement tools and a wide range of industrial materials, The Digital Forge is purpose-built to integrate into existing manufacturing ecosystems. With the Digital Forge, users can share parts across their organization, and monitor fleet performance from a central location.

About Markforged

Markforged (NYSE: MKFG) is enabling more resilient and flexible supply chains by bringing industrial 3D printing right to the factory floor. Our additive manufacturing platform The Digital Forge allows manufacturers to create strong, accurate parts in both metal and advanced composites. With over 10,000 customers in 70+ countries, we’re bringing on-demand industrial production to the point of need. We are headquartered in Waltham, Mass where we design the hardware, software and advanced materials that makes The Digital Forge reliable and easy to use. To learn more, visit www.markforged.com.

Special Note Regarding Forward-Looking Statements

This press release contains forward-looking statements that are based on beliefs and assumptions and on information currently available. In some cases, you can identify forward-looking statements by the following words: “may,” “will,” “could,” “would,” “should,” “expect,” “intend,” “plan,” “strategy,” “anticipate,” “believe,” “estimate,” “predict,” “project,” “potential,” “continue,” “ongoing,” “opportunity” or the negative of these terms or other comparable terminology, although not all forward-looking statements contain these words. These statements involve risks, uncertainties and other factors that may cause actual results, levels of activity, performance or achievements to be materially different from the information expressed or implied by these forward-looking statements. Although Markforged believes that it has a reasonable basis for each forward-looking statement contained in this press release, Markforged cautions you that these statements are based on a combination of facts and factors currently known by it and its projections of the future, about which it cannot be certain. Forward-looking statements in this press release include, but are not limited to, statements regarding the impact of the newly-announced FX10 printer on the manufacturing industry and Markforged, statements related to product development and innovation, and statements regarding the potential benefits to consumers of Markforged products including, but not limited to, the FX10 printer; our ability to fulfill orders for our products in a timely fashion in the future; expected growth of the size of and opportunity to increase our addressable market; the timing of launches and the rate and extent of adoption of our products, including, but not limited to, our most recently introduced products; market trends in the manufacturing industry; the effects of macroeconomic factors; and the benefits to consumers, functionality and applications of Markforged’s products. Markforged cannot assure you that the forward-looking statements in this press release will prove to be accurate. These forward looking statements are subject to a number of risks and uncertainties, including, among others, general economic, political and business conditions; the ability of Markforged to maintain its listing on the New York Stock Exchange; the effect of uncertainties related to economic downturns and global supply chain disruptions on Markforged’s business and financial results; the outcome of any legal proceedings against Markforged; and those factors discussed under the header “Risk Factors” in Markforged’s most recent periodic and other filings with the SEC. Furthermore, if the forward-looking statements prove to be inaccurate, the inaccuracy may be material. In light of the significant uncertainties in these forward-looking statements, you should not regard these statements as a representation or warranty by us or any other person that Markforged will achieve its objectives and plans in any specified time frame, or at all. The forward-looking statements in this press release represent Markforged’s views as of the date of this press release. Markforged anticipates that subsequent events and developments will cause its views to change. However, while Markforged may elect to update these forward-looking statements at some point in the future, Markforged has no current intention of doing so except to the extent required by applicable law. You should, therefore, not rely on these forward-looking statements as representing Markforged’s views as of any date subsequent to the date of this press release.

View source version on businesswire.com: https://www.businesswire.com/news/home/20231107499924/en/

Contacts

Media contact: Samuel Manning, Principal Public Relations

sam.manning@markforged.com

Investor contact: Austin Bohlig, Director, Investor Relations

austin.bohlig@markforged.com

More News

View More

Recent Quotes

View MoreQuotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.